The two most common types of railings today are stainless steel railings and powder-coated iron railings. Both come with their own advantages and disadvantages, leaving many people uncertain about which option to choose. This article by Butraco will provide a detailed comparison between stainless steel railings and powder-coated iron railings, thereby making the most suitable decision for project.

Below are the outstanding features of iron and stainless steel materials.

Iron is a chemical element listed in the Interactive periodic table with the symbol Fe and an atomic number of 26. It belongs to Group VIIIB and Period 4. When used as a material for processing, iron requires a protective layer through powder coating. Powder coating is a type of powder paint that is coated on the surface of iron materials using the principle of electromagnetism.

Advantages of powder coating:

Inox (also known as stainless steel) is an alloy of iron with at least 10.5% chromium. The common point of this type of stainless steel alloy is that it is less likely to change color or corrode compared to other common types of steel.

In general, stainless steel is a type of steel with more than 11% chromium. This structure has created a super durable protective film against corrosion. Nickel is also the main component of this material that brings stability to the Austenitic phase with excellent machining skills for stainless steel products.

Advantages

Is powder-coated iron railing durable? Powder-coated iron railings have high load-bearing capacity, helping them to withstand strong external impacts. The powder-coating process also strengthens the capacity to resist scratches and impacts, making the railing maintain its beauty and technical properties. However, if not maintained regularly, the paint layer can easily peel off, causing the situation of rust and damage to iron railings.

Compared to powder-coated iron railings, stainless steel railings are more durable and do not rust in harsh weather conditions.

Below is the quotations of stainless steel railings and powder-coated iron railings for reference:

Butraco is pleased to submit the quotation of powder-coated iron railings for your reference:

The price of iron railing products also depends on:

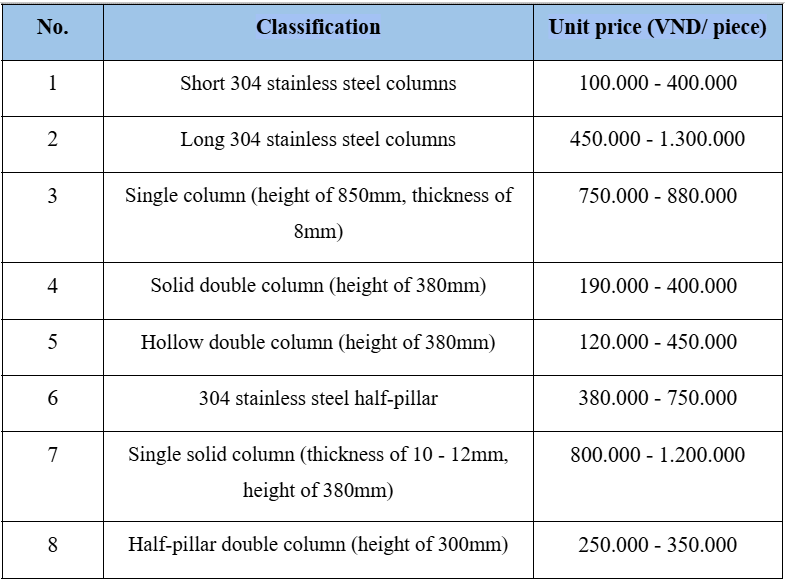

Below is the quotation of 304 stainless steel railings for reference:

Butraco is a direct supplier and processor of 304 stainless steel railings. Especially, Butraco’s stainless steel railings are often used to make balcony railings, stair railings, terrace railings, bridge railings and so on for many large and small projects such as houses, hotels, motels and inns, commercial centers, schools, hospitals, industrial factories, warehouses, large-scale projects etc.

Advantages of stainless steel railings processed by Butraco :

Butraco Vietnam Co., Ltd is dedicated to offering customers top-quality products and stands as a leading company in the manufacturing and processing of interior products made from stainless steel, steel, roofing sheets, and other mechanical processing goods. Guided by the principles of “Quality - Professionalism – Efficiency”, Butraco is confident in achieving success across all areas, deserving the trust of its customers and partners.

-------------------------------------------

Butraco Vietnam - Provider of on-demand CNC laser cutting services and sheet metal processing