Grating panels, also known as grating floor panels, consist of parallel load-bearing bars that can be either flat or serrated, with equal spacing between them. These bars are held upright by twisted square crossbars, forming a strong mesh structure. Today, grating panels are widely used in construction projects, factories, and even in everyday life. Let’s explore this versatile material with Butraco through the article below!

A grating panel is a multi-functional material made from steel, aluminum, stainless steel, and other materials, and is often referred to as a grating cover. The metal bars in a grating panel are arranged in parallel with equal spacing and are held in place by twisted square crossbars, forming a steel mesh panel.

The load-bearing grating panels are produced using non-corrosive bars. Grating panels are typically composed of:

Flat Bars: These bars have low carbon content (e.g., SS400, A36 steel, Q345B, Q235, or C45). They usually range in thickness from 2mm to 12mm and in height from 20mm to 150mm.

Twisted Square Bars: These bars connect the flat bars together. They are typically 6×6 mm in size and are designed with a twisted pattern.

Common Grating Panel Designs:

Specifications and Dimensions of Grating Panels:

Grating panels offer high corrosion resistance and open surfaces of up to 80%, making them ideal for a wide range of applications. They are commonly used in power plants, oil and gas industries, chemical and machinery industries, parking lots, shipbuilding and seaports, etc. Additionally, grating panels are widely applied in floors, walkways, platforms, and covers.

Specific Applications of Grating Panels:

The production of grating panels follows four main stages:

Grating panels are constructed from flat steel bars and crossbars. Therefore, the first stage of production involves preparing the load-bearing flat bars according to the grating panel blueprint.

After preparing the flat bars, the next step is to prepare the crossbars. This preparation involves three steps:

Once the main components are ready, the production team proceeds to weld the grating panel. This process includes:

After welding, the grating panel is coated with an appropriate protective layer based on the material. Once coated, the product undergoes final inspection to identify any defects, which are corrected immediately to ensure the product meets quality standards.

The grating panels produced by Butraco offer the following advantages:

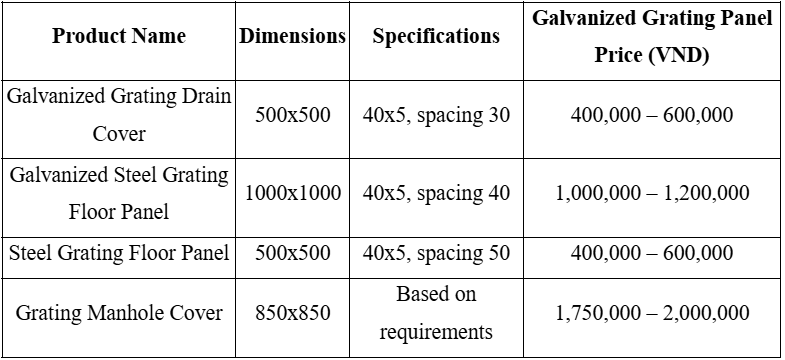

Below is a reference price range for galvanized grating panels from VND 400,000 to 2,000,000 per panel.

Note: This price list is for reference only. For accurate pricing, please contact Butraco directly. Their technical team will provide detailed consultation and a precise quote within the day.

If you are interested in mechanical processing products or want to find a reputable and quality manufacturer and distributor, Butraco is always happy to advise and provide all you need with the motto “What you need, we have it all”. With a team of experienced and enthusiastic employees, we have gradually affirmed our position as a leading company in the field of manufacturing and processing interior materials with corrugated iron, stainless steel, and mechanical processing products.

-------------------------------------------